FPT Industrial

o dużym obciążeniu, rekreacyjnych, a nawet regatowych.

dystrybutor BUKH na Polskę

Ponad 100 lat doświadczenia umożliwiło uzyskanie produktów o najwyższej bezawaryjności na rynku.

JP Marine liderem rozwiązań

w technologiach morskich

Od lat zajmujemy się optymalnym, kompleksowym doborem układów napędowych – zarówno do nowych łodzi, jak i tych przebudowywanych. Dobieramy układy paliwowe, chłodzenia, zasilania, wentylacji, wydechów mokrych i suchych, jak i kształtu oraz parametrów gęstościowych tub z indywidualnym systemem klejenia.

Na swoim koncie mamy setki realizacji, zarówno jednostek komercyjnych, prywatnych oraz militarnych.

Wybrane z naszej oferty

Posiadamy własne zaplecze projektowe do:

- optymalnego – kompleksowego doboru układów napędowych (silnik, skrzynia biegów, wał, śruba) do łodzi nowych jak i przebudowywanych (rybackie, patrolowe, ratownicze, rekreacyjne)

- doboru układów paliwowych, chłodzenia, zasilania, wentylacji, wydechów mokrych i suchych

- doboru kształtu i parametrów gęstościowych tub z indywidualnym systemem klejenia – montażu do różnego rodzaju łodzi (RIB, patrolowe, holowniki)

- przebudowy, budowy od podstaw łodzi kompozytowych różnego rodzaju w najnowszych w technologiach infuzji epoksydowej, winylo – estrowej z użyciem włókien węglowych czy Kevlarowych.

JP Marine

autoryzowany dystrybutor:

- silników morskich i generatorów FPT Industrial (Iveco) w tym Stage V

- silników morskich BUKH SOLAS

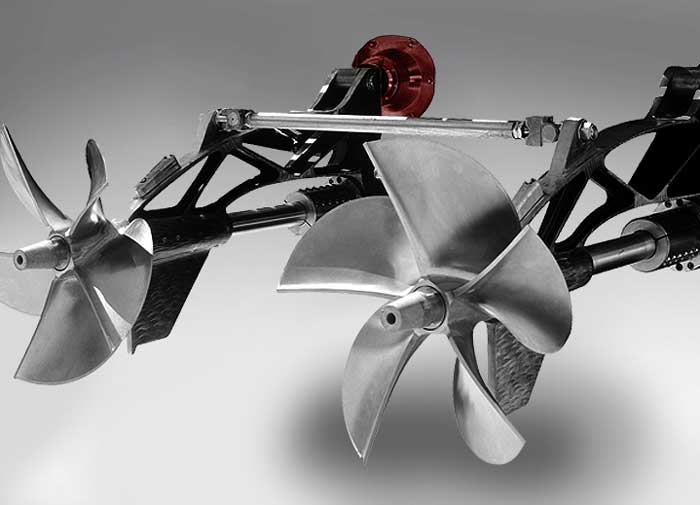

- śrub napędowych, linii wału w tym napędów powierzchniowych France Helices

- pędników typu jet Castoldi

- układów dopalania spalin SCR do najwyższych norm środowiskowych

Posiadamy wieloletniedoświadczenie w montażui serwisie silników morskichi jachtowych

Dysponujemy zapleczem magazynowym z dużą ilością części zamiennych do jachtów motorowych, kutrów. W stałej ofercie posiadamy ponad 1000 sztuk śrub napędowych.

- Diagnoza źródeł wibracji

- Gwarancja prędkości przy prawidłowych danych wejściowych

Pełne oprzyrządowanie diagnostyczne umożliwia szybką diagnozę i usunięcie usterki. Wykonujemy remonty kapitalne wszystkich oferowanych silników.

Najnowsze

wiadomości

Zobacz co się u nas dzieje i bądź na bieżąco z najnowszymi wydarzeniami.